Ixabiso levenkile ethengisa impahla yaseTshayina njenge568 eMigangatho yeRabha O Ringi yeSilicone O-Ringi Umbala werabha O uMenzi weRingi

Ixabiso levenkile ethengisa impahla yaseTshayina njenge568 eMigangatho yeRabha O Ringi yeSilicone O-Ringi Umbala werabha O uMenzi weRingi

Sinyanzelisa ukubonelela ngemveliso esemgangathweni enengqiqo yeshishini elilungileyo, umvuzo onyanisekileyo kunye noncedo olulungileyo nolukhawulezayo. akuyi kukuzisela kuphela i-premium yekhwalithi yemveliso okanye inkonzo kunye nenzuzo enkulu, kodwa mhlawumbi eyona nto ibalulekileyo idla ngokuhlala kwimarike engapheliyo ye-Wholesale Price I-China As568 Standard Rubber O Ring Silicone O-Ring Color Rubber O Umenzi weRingi, Ukuba kunokwenzeka, qiniseka ukuba uthumela iimfuno zakho ngoluhlu oluneenkcukacha ezibandakanya isitayile / into kunye nobungakanani obufunayo. Siza kuthumela amaxabiso ethu amakhulu kuwe.

Sinyanzelisa ukubonelela ngemveliso esemgangathweni enengqiqo yeshishini elilungileyo, umvuzo onyanisekileyo kunye noncedo olulungileyo nolukhawulezayo. ayizi kukuzisela kuphela iprimiyamu yemveliso okanye inkonzo kunye nenzuzo enkulu, kodwa eyona nto ibalulekileyo idla ngokuhlala kwimarike engapheliyo.China FKM O Ring kunye Rubber O Ring, Ubuchwephesha bethu bobugcisa, inkonzo elungele umthengi, kunye nentengiso ekhethekileyo isenza ukuba / igama lenkampani libe ukhetho lokuqala lwabathengi kunye nabathengisi. Kudala sikhangela umbuzo wakho. Masiseke intsebenziswano ngoku!

Okokuqala -nceda ujonge ubungakanani oring AS568

| Ubukhulu be-AS568 | Isazisi segama | Igama elithi C/S | I-ID yeMilinganiso ngee-intshi | ± i-ID | Imilinganiselo CS ngee-intshi | ± CS | I-ID yeMilinganiso kwi-mm | ± i-ID | Imilinganiselo CS kwi mm | ± C/S | ||||||||||

| -1 | 1/32 | 1/32 | 0.029 | 0.004 | 0.040 | 0.003 | 0.74 | 0.10 | 1.02 | 0.08 | ||||||||||

| -2 | 3/64 | 3/64 | 0.042 | 0.004 | 0.050 | 0.003 | 1.07 | 0.10 | 1.27 | 0.08 | ||||||||||

| -3 | 1/16 | 1/16 | 0.056 | 0.004 | 0.060 | 0.003 | 1.42 | 0.10 | 1.52 | 0.08 | ||||||||||

| -4 | 5/64 | 1/16 | 0.070 | 0.005 | 0.070 | 0.003 | 1.78 | 0.13 | 1.78 | 0.08 | ||||||||||

| -5 | 3/32 | 1/16 | 0.101 | 0.005 | 0.070 | 0.003 | 2.57 | 0.13 | 1.78 | 0.08 | ||||||||||

| -6 | 1/8 | 1/16 | 0.114 | 0.005 | 0.070 | 0.003 | 2.90 | 0.13 | 1.78 | 0.08 | ||||||||||

| -7 | 5/32 | 1/16 | 0.145 | 0.005 | 0.070 | 0.003 | 3.68 | 0.13 | 1.78 | 0.08 | ||||||||||

| -8 | 3/16 | 1/16 | 0.176 | 0.005 | 0.070 | 0.003 | 4.47 | 0.13 | 1.78 | 0.08 | ||||||||||

| -9 | 7/32 | 1/16 | 0.208 | 0.005 | 0.070 | 0.003 | 5.28 | 0.13 | 1.78 | 0.08 | ||||||||||

| -10 | 1/4 | 1/16 | 0.239 | 0.005 | 0.070 | 0.003 | 6.07 | 0.13 | 1.78 | 0.08 | ||||||||||

| -11 | 5/16 | 1/16 | 0.301 | 0.005 | 0.070 | 0.003 | 7.65 | 0.13 | 1.78 | 0.08 | ||||||||||

| -12 | 3/8 | 1/16 | 0.364 | 0.005 | 0.070 | 0.003 | 9.25 | 0.13 | 1.78 | 0.08 | ||||||||||

| -13 | 7/16 | 1/16 | 0.426 | 0.005 | 0.070 | 0.003 | 10.82 | 0.13 | 1.78 | 0.08 | ||||||||||

| -14 | 1/2 | 1/16 | 0.489 | 0.005 | 0.070 | 0.003 | 12.42 | 0.13 | 1.78 | 0.08 | ||||||||||

| -15 | 9/16 | 1/16 | 0.551 | 0.007 | 0.070 | 0.003 | 14.00 | 0.18 | 1.78 | 0.08 | ||||||||||

| -16 | 5/8 | 1/16 | 0.614 | 0.009 | 0.070 | 0.003 | 15.60 | 0.23 | 1.78 | 0.08 | ||||||||||

| -17 | 11/16 | 1/16 | 0.676 | 0.009 | 0.070 | 0.003 | 17.17 | 0.23 | 1.78 | 0.08 | ||||||||||

| -18 | 3/4 | 1/16 | 0.739 | 0.009 | 0.070 | 0.003 | 18.77 | 0.23 | 1.78 | 0.08 | ||||||||||

| -19 | 13/16 | 1/16 | 0.801 | 0.009 | 0.070 | 0.003 | 20.35 | 0.23 | 1.78 | 0.08 | ||||||||||

| -20 | 7/8 | 1/16 | 0.864 | 0.009 | 0.070 | 0.003 | 21.95 | 0.23 | 1.78 | 0.08 | ||||||||||

| -21 | 15/16 | 1/16 | 0.926 | 0.009 | 0.070 | 0.003 | 23.52 | 0.23 | 1.78 | 0.08 | ||||||||||

| -22 | 1 | 1/16 | 0.989 | 0.010 | 0.070 | 0.003 | 25.12 | 0.25 | 1.78 | 0.08 | ||||||||||

| -23 | 1 1/16 | 1/16 | 1.051 | 0.010 | 0.070 | 0.003 | 26.70 | 0.25 | 1.78 | 0.08 | ||||||||||

| -24 | 1 1/8 | 1/16 | 1.114 | 0.010 | 0.070 | 0.003 | 28.30 | 0.25 | 1.78 | 0.08 | ||||||||||

| -25 | 1 3/16 | 1/16 | 1.176 | 0.011 | 0.070 | 0.003 | 29.87 | 0.28 | 1.78 | 0.08 | ||||||||||

| -26 | 1 1/4 | 1/16 | 1.239 | 0.011 | 0.070 | 0.003 | 31.47 | 0.28 | 1.78 | 0.08 | ||||||||||

| -27 | 1 5/16 | 1/16 | 1.301 | 0.011 | 0.070 | 0.003 | 33.05 | 0.28 | 1.78 | 0.08 | ||||||||||

| -28 | 1 3/8 | 1/16 | 1.364 | 0.013 | 0.070 | 0.003 | 34.65 | 0.33 | 1.78 | 0.08 | ||||||||||

| -29 | 1 1/2 | 1/16 | 1.489 | 0.013 | 0.070 | 0.003 | 37.82 | 0.33 | 1.78 | 0.08 | ||||||||||

| -30 | 1 5/8 | 1/16 | 1.614 | 0.013 | 0.070 | 0.003 | 41.00 | 0.33 | 1.78 | 0.08 | ||||||||||

| -31 | 1 3/4 | 1/16 | 1.739 | 0.015 | 0.070 | 0.003 | 44.17 | 0.38 | 1.78 | 0.08 | ||||||||||

| -32 | 1 7/8 | 1/16 | 1.864 | 0.015 | 0.070 | 0.003 | 47.35 | 0.38 | 1.78 | 0.08 | ||||||||||

| -33 | 2 | 1/16 | 1.989 | 0.018 | 0.070 | 0.003 | 50.52 | 0.46 | 1.78 | 0.08 | ||||||||||

| -34 | 2 1/8 | 1/16 | 2.114 | 0.018 | 0.070 | 0.003 | 53.70 | 0.46 | 1.78 | 0.08 | ||||||||||

| -35 | 2 1/4 | 1/16 | 2.239 | 0.018 | 0.070 | 0.003 | 56.87 | 0.46 | 1.78 | 0.08 | ||||||||||

| -36 | 2 3/8 | 1/16 | 2.364 | 0.018 | 0.070 | 0.003 | 60.05 | 0.46 | 1.78 | 0.08 | ||||||||||

| -37 | 2 1/2 | 1/16 | 2.489 | 0.018 | 0.070 | 0.003 | 63.22 | 0.46 | 1.78 | 0.08 | ||||||||||

| -38 | 2 5/8 | 1/16 | 2.614 | 0.020 | 0.070 | 0.003 | 66.40 | 0.51 | 1.78 | 0.08 | ||||||||||

| -39 | 2 3/4 | 1/16 | 2.739 | 0.020 | 0.070 | 0.003 | 69.57 | 0.51 | 1.78 | 0.08 | ||||||||||

| -40 | 2 7/8 | 1/16 | 2.864 | 0.020 | 0.070 | 0.003 | 72.75 | 0.51 | 1.78 | 0.08 | ||||||||||

| -41 | 3 | 1/16 | 2.989 | 0.024 | 0.070 | 0.003 | 75.92 | 0.61 | 1.78 | 0.08 | ||||||||||

| -42 | 3 1/4 | 1/16 | 3.239 | 0.024 | 0.070 | 0.003 | 82.27 | 0.61 | 1.78 | 0.08 | ||||||||||

| -43 | 3 1/2 | 1/16 | 3.489 | 0.024 | 0.070 | 0.003 | 88.62 | 0.61 | 1.78 | 0.08 | ||||||||||

| -44 | 3 3/4 | 1/16 | 3.739 | 0.027 | 0.070 | 0.003 | 94.97 | 0.69 | 1.78 | 0.08 | ||||||||||

| -45 | 4 | 1/16 | 3.989 | 0.027 | 0.070 | 0.003 | 101.32 | 0.69 | 1.78 | 0.08 | ||||||||||

| -46 | 4 1/4 | 1/16 | 4.239 | 0.030 | 0.070 | 0.003 | 107.67 | 0.76 | 1.78 | 0.08 | ||||||||||

| -47 | 4 1/2 | 1/16 | 4.489 | 0.030 | 0.070 | 0.003 | 114.02 | 0.76 | 1.78 | 0.08 | ||||||||||

| -48 | 4 3/4 | 1/16 | 4.739 | 0.030 | 0.070 | 0.003 | 120.37 | 0.76 | 1.78 | 0.08 | ||||||||||

| -49 | 5 | 1/16 | 4.989 | 0.037 | 0.070 | 0.003 | 126.72 | 0.94 | 1.78 | 0.08 | ||||||||||

| -50 | 5 1/4 | 1/16 | 5.239 | 0.037 | 0.070 | 0.003 | 133.07 | 0.94 | 1.78 | 0.08 | ||||||||||

| -102 | 1/16 | 3/32 | 0.049 | 0.005 | 0.103 | 0.003 | 1.24 | 0.13 | 2.62 | 0.08 | ||||||||||

| -103 | 3/32 | 3/32 | 0.081 | 0.005 | 0.103 | 0.003 | 2.06 | 0.13 | 2.62 | 0.08 | ||||||||||

| -104 | 1/8 | 3/32 | 0.112 | 0.005 | 0.103 | 0.003 | 2.84 | 0.13 | 2.62 | 0.08 | ||||||||||

| -105 | 5/32 | 3/32 | 0.143 | 0.005 | 0.103 | 0.003 | 3.63 | 0.13 | 2.62 | 0.08 | ||||||||||

| -106 | 3/16 | 3/32 | 0.174 | 0.005 | 0.103 | 0.003 | 4.42 | 0.13 | 2.62 | 0.08 | ||||||||||

| -107 | 7/32 | 3/32 | 0.206 | 0.005 | 0.103 | 0.003 | 5.23 | 0.13 | 2.62 | 0.08 | ||||||||||

| -108 | 1/4 | 3/32 | 0.237 | 0.005 | 0.103 | 0.003 | 6.02 | 0.13 | 2.62 | 0.08 | ||||||||||

| -109 | 5/16 | 3/32 | 0.299 | 0.005 | 0.103 | 0.003 | 7.59 | 0.13 | 2.62 | 0.08 | ||||||||||

| -110 | 3/8 | 3/32 | 0.362 | 0.005 | 0.103 | 0.003 | 9.19 | 0.13 | 2.62 | 0.08 | ||||||||||

| -111 | 7/16 | 3/32 | 0.424 | 0.005 | 0.103 | 0.003 | 10.77 | 0.13 | 2.62 | 0.08 | ||||||||||

| -112 | 1/2 | 3/32 | 0.487 | 0.005 | 0.103 | 0.003 | 12.37 | 0.13 | 2.62 | 0.08 | ||||||||||

| -113 | 9/16 | 3/32 | 0.549 | 0.007 | 0.103 | 0.003 | 13.94 | 0.18 | 2.62 | 0.08 | ||||||||||

| -114 | 5/8 | 3/32 | 0.612 | 0.009 | 0.103 | 0.003 | 15.54 | 0.23 | 2.62 | 0.08 | ||||||||||

| -115 | 11/16 | 3/32 | 0.674 | 0.009 | 0.103 | 0.003 | 17.12 | 0.23 | 2.62 | 0.08 | ||||||||||

| -116 | 3/4 | 3/32 | 0.737 | 0.009 | 0.103 | 0.003 | 18.72 | 0.23 | 2.62 | 0.08 | ||||||||||

| -117 | 13/16 | 3/32 | 0.799 | 0.010 | 0.103 | 0.003 | 20.29 | 0.25 | 2.62 | 0.08 | ||||||||||

| -118 | 7/8 | 3/32 | 0.862 | 0.010 | 0.103 | 0.003 | 21.89 | 0.25 | 2.62 | 0.08 | ||||||||||

| -119 | 15/16 | 3/32 | 0.924 | 0.010 | 0.103 | 0.003 | 23.47 | 0.25 | 2.62 | 0.08 | ||||||||||

| -120 | 1 | 3/32 | 0.987 | 0.010 | 0.103 | 0.003 | 25.07 | 0.25 | 2.62 | 0.08 | ||||||||||

| -121 | 1 1/16 | 3/32 | 1.049 | 0.010 | 0.103 | 0.003 | 26.64 | 0.25 | 2.62 | 0.08 | ||||||||||

| -122 | 1 1/8 | 3/32 | 1.112 | 0.010 | 0.103 | 0.003 | 28.24 | 0.25 | 2.62 | 0.08 | ||||||||||

| -123 | 1 3/16 | 3/32 | 1.174 | 0.012 | 0.103 | 0.003 | 29.82 | 0.30 | 2.62 | 0.08 | ||||||||||

| -124 | 1 1/4 | 3/32 | 1.237 | 0.012 | 0.103 | 0.003 | 31.42 | 0.30 | 2.62 | 0.08 | ||||||||||

| -125 | 1 5/16 | 3/32 | 1.299 | 0.012 | 0.103 | 0.003 | 32.99 | 0.30 | 2.62 | 0.08 | ||||||||||

| -126 | 1 3/8 | 3/32 | 1.362 | 0.012 | 0.103 | 0.003 | 34.59 | 0.30 | 2.62 | 0.08 | ||||||||||

| -127 | 1 7/16 | 3/32 | 1.424 | 0.012 | 0.103 | 0.003 | 36.17 | 0.30 | 2.62 | 0.08 | ||||||||||

| -128 | 1 1/2 | 3/32 | 1.487 | 0.012 | 0.103 | 0.003 | 37.77 | 0.30 | 2.62 | 0.08 | ||||||||||

| -129 | 1 9/16 | 3/32 | 1.549 | 0.015 | 0.103 | 0.003 | 39.34 | 0.38 | 2.62 | 0.08 | ||||||||||

| -130 | 1 5/8 | 3/32 | 1.612 | 0.015 | 0.103 | 0.003 | 40.94 | 0.38 | 2.62 | 0.08 | ||||||||||

| -131 | 1 11/16 | 3/32 | 1.674 | 0.015 | 0.103 | 0.003 | 42.52 | 0.38 | 2.62 | 0.08 | ||||||||||

| -132 | 1 3/4 | 3/32 | 1.737 | 0.015 | 0.103 | 0.003 | 44.12 | 0.38 | 2.62 | 0.08 | ||||||||||

| -133 | 1 13/16 | 3/32 | 1.799 | 0.015 | 0.103 | 0.003 | 45.69 | 0.38 | 2.62 | 0.08 | ||||||||||

| -134 | 1 7/8 | 3/32 | 1.862 | 0.015 | 0.103 | 0.003 | 47.29 | 0.38 | 2.62 | 0.08 | ||||||||||

| -135 | 1 15/16 | 3/32 | 1.925 | 0.017 | 0.103 | 0.003 | 48.90 | 0.43 | 2.62 | 0.08 | ||||||||||

| -136 | 2 | 3/32 | 1.987 | 0.017 | 0.103 | 0.003 | 50.47 | 0.43 | 2.62 | 0.08 | ||||||||||

| -137 | 2 1/16 | 3/32 | 2.050 | 0.017 | 0.103 | 0.003 | 52.07 | 0.43 | 2.62 | 0.08 | ||||||||||

| -138 | 2 1/8 | 3/32 | 2.112 | 0.017 | 0.103 | 0.003 | 53.64 | 0.43 | 2.62 | 0.08 | ||||||||||

| -139 | 2 3/16 | 3/32 | 2.175 | 0.017 | 0.103 | 0.003 | 55.25 | 0.43 | 2.62 | 0.08 | ||||||||||

| -140 | 2 1/4 | 3/32 | 2.237 | 0.017 | 0.103 | 0.003 | 56.82 | 0.43 | 2.62 | 0.08 | ||||||||||

| -141 | 2 5/16 | 3/32 | 2.300 | 0.020 | 0.103 | 0.003 | 58.42 | 0.51 | 2.62 | 0.08 | ||||||||||

| -142 | 2 3/8 | 3/32 | 2.362 | 0.020 | 0.103 | 0.003 | 59.99 | 0.51 | 2.62 | 0.08 | ||||||||||

| -143 | 2 7/16 | 3/32 | 2.425 | 0.020 | 0.103 | 0.003 | 61.60 | 0.51 | 2.62 | 0.08 | ||||||||||

| -144 | 2 1/2 | 3/32 | 2.487 | 0.020 | 0.103 | 0.003 | 63.17 | 0.51 | 2.62 | 0.08 | ||||||||||

| -145 | 2 9/16 | 3/32 | 2.550 | 0.020 | 0.103 | 0.003 | 64.77 | 0.51 | 2.62 | 0.08 | ||||||||||

| -146 | 2 5/8 | 3/32 | 2.612 | 0.020 | 0.103 | 0.003 | 66.34 | 0.51 | 2.62 | 0.08 | ||||||||||

| -147 | 2 11/16 | 3/32 | 2.675 | 0.022 | 0.103 | 0.003 | 67.95 | 0.56 | 2.62 | 0.08 | ||||||||||

| -148 | 2 3/4 | 3/32 | 2.737 | 0.022 | 0.103 | 0.003 | 69.52 | 0.56 | 2.62 | 0.08 | ||||||||||

| -149 | 2 13/16 | 3/32 | 2.800 | 0.022 | 0.103 | 0.003 | 71.12 | 0.56 | 2.62 | 0.08 | ||||||||||

| -150 | 2 7/8 | 3/32 | 2.862 | 0.022 | 0.103 | 0.003 | 72.69 | 0.56 | 2.62 | 0.08 | ||||||||||

| -151 | 3 | 3/32 | 2.987 | 0.024 | 0.103 | 0.003 | 75.87 | 0.61 | 2.62 | 0.08 | ||||||||||

| -152 | 3 1/4 | 3/32 | 3.237 | 0.024 | 0.103 | 0.003 | 82.22 | 0.61 | 2.62 | 0.08 | ||||||||||

| -153 | 3 1/2 | 3/32 | 3.487 | 0.024 | 0.103 | 0.003 | 88.57 | 0.61 | 2.62 | 0.08 | ||||||||||

| -154 | 3 3/4 | 3/32 | 3.737 | 0.028 | 0.103 | 0.003 | 94.92 | 0.71 | 2.62 | 0.08 | ||||||||||

| -155 | 4 | 3/32 | 3.987 | 0.028 | 0.103 | 0.003 | 101.27 | 0.71 | 2.62 | 0.08 | ||||||||||

| -156 | 4 1/4 | 3/32 | 4.237 | 0.030 | 0.103 | 0.003 | 107.62 | 0.76 | 2.62 | 0.08 | ||||||||||

| -157 | 4 1/2 | 3/32 | 4.487 | 0.030 | 0.103 | 0.003 | 113.97 | 0.76 | 2.62 | 0.08 | ||||||||||

| -158 | 4 3/4 | 3/32 | 4.737 | 0.030 | 0.103 | 0.003 | 120.32 | 0.76 | 2.62 | 0.08 | ||||||||||

| -159 | 5 | 3/32 | 4.987 | 0.035 | 0.103 | 0.003 | 126.67 | 0.89 | 2.62 | 0.08 | ||||||||||

| -160 | 5 1/4 | 3/32 | 5.237 | 0.035 | 0.103 | 0.003 | 133.02 | 0.89 | 2.62 | 0.08 | ||||||||||

| -161 | 5 1/2 | 3/32 | 5.487 | 0.035 | 0.103 | 0.003 | 139.37 | 0.89 | 2.62 | 0.08 | ||||||||||

| -162 | 5 3/4 | 3/32 | 5.737 | 0.035 | 0.103 | 0.003 | 145.72 | 0.89 | 2.62 | 0.08 | ||||||||||

| -163 | 6 | 3/32 | 5.987 | 0.035 | 0.103 | 0.003 | 152.07 | 0.89 | 2.62 | 0.08 | ||||||||||

| -164 | 6 1/4 | 3/32 | 6.237 | 0.040 | 0.103 | 0.003 | 158.42 | 1.02 | 2.62 | 0.08 | ||||||||||

| -165 | 6 1/2 | 3/32 | 6.487 | 0.040 | 0.103 | 0.003 | 164.77 | 1.02 | 2.62 | 0.08 | ||||||||||

| -166 | 6 3/4 | 3/32 | 6.737 | 0.040 | 0.103 | 0.003 | 171.12 | 1.02 | 2.62 | 0.08 | ||||||||||

| -167 | 7 | 3/32 | 6.987 | 0.040 | 0.103 | 0.003 | 177.47 | 1.02 | 2.62 | 0.08 | ||||||||||

| -168 | 7 1/4 | 3/32 | 7.237 | 0.045 | 0.103 | 0.003 | 183.82 | 1.14 | 2.62 | 0.08 | ||||||||||

| -169 | 7 1/2 | 3/32 | 7.487 | 0.045 | 0.103 | 0.003 | 190.17 | 1.14 | 2.62 | 0.08 | ||||||||||

| -170 | 7 3/4 | 3/32 | 7.737 | 0.045 | 0.103 | 0.003 | 196.52 | 1.14 | 2.62 | 0.08 | ||||||||||

| -171 | 8 | 3/32 | 7.987 | 0.045 | 0.103 | 0.003 | 202.87 | 1.14 | 2.62 | 0.08 | ||||||||||

| -172 | 8 1/4 | 3/32 | 8.237 | 0.050 | 0.103 | 0.003 | 209.22 | 1.27 | 2.62 | 0.08 | ||||||||||

| -173 | 8 1/2 | 3/32 | 8.487 | 0.050 | 0.103 | 0.003 | 215.57 | 1.27 | 2.62 | 0.08 | ||||||||||

| -174 | 8 3/4 | 3/32 | 8.737 | 0.050 | 0.103 | 0.003 | 221.92 | 1.27 | 2.62 | 0.08 | ||||||||||

| -175 | 9 | 3/32 | 8.987 | 0.050 | 0.103 | 0.003 | 228.27 | 1.27 | 2.62 | 0.08 | ||||||||||

| -176 | 9 1/4 | 3/32 | 9.237 | 0.055 | 0.103 | 0.003 | 234.62 | 1.40 | 2.62 | 0.08 | ||||||||||

| -177 | 9 1/2 | 3/32 | 9.487 | 0.055 | 0.103 | 0.003 | 240.97 | 1.40 | 2.62 | 0.08 | ||||||||||

| -178 | 9 3/4 | 3/32 | 9.737 | 0.055 | 0.103 | 0.003 | 247.32 | 1.40 | 2.62 | 0.08 | ||||||||||

| -201 | 3/16 | 1/8 | 0.171 | 0.005 | 0.139 | 0.004 | 4.34 | 0.13 | 3.53 | 0.10 | ||||||||||

| -202 | 1/4 | 1/8 | 0.234 | 0.005 | 0.139 | 0.004 | 5.94 | 0.13 | 3.53 | 0.10 | ||||||||||

| -203 | 5/16 | 1/8 | 0.296 | 0.005 | 0.139 | 0.004 | 7.52 | 0.13 | 3.53 | 0.10 | ||||||||||

| -204 | 3/8 | 1/8 | 0.359 | 0.005 | 0.139 | 0.004 | 9.12 | 0.13 | 3.53 | 0.10 | ||||||||||

| -205 | 7/16 | 1/8 | 0.421 | 0.005 | 0.139 | 0.004 | 10.69 | 0.13 | 3.53 | 0.10 | ||||||||||

| -206 | 1/2 | 1/8 | 0.484 | 0.005 | 0.139 | 0.004 | 12.29 | 0.13 | 3.53 | 0.10 | ||||||||||

| -207 | 9/16 | 1/8 | 0.546 | 0.007 | 0.139 | 0.004 | 13.87 | 0.18 | 3.53 | 0.10 | ||||||||||

| -208 | 5/8 | 1/8 | 0.609 | 0.009 | 0.139 | 0.004 | 15.47 | 0.23 | 3.53 | 0.10 | ||||||||||

| -209 | 11/16 | 1/8 | 0.671 | 0.009 | 0.139 | 0.004 | 17.04 | 0.23 | 3.53 | 0.10 | ||||||||||

| -210 | 3/4 | 1/8 | 0.734 | 0.010 | 0.139 | 0.004 | 18.64 | 0.25 | 3.53 | 0.10 | ||||||||||

| -211 | 13/16 | 1/8 | 0.796 | 0.010 | 0.139 | 0.004 | 20.22 | 0.25 | 3.53 | 0.10 | ||||||||||

| -212 | 7/8 | 1/8 | 0.859 | 0.010 | 0.139 | 0.004 | 21.82 | 0.25 | 3.53 | 0.10 | ||||||||||

| -213 | 15/16 | 1/8 | 0.921 | 0.010 | 0.139 | 0.004 | 23.39 | 0.25 | 3.53 | 0.10 | ||||||||||

| -214 | 1 | 1/8 | 0.984 | 0.010 | 0.139 | 0.004 | 24.99 | 0.25 | 3.53 | 0.10 | ||||||||||

| -215 | 1 1/16 | 1/8 | 1.046 | 0.010 | 0.139 | 0.004 | 26.57 | 0.25 | 3.53 | 0.10 | ||||||||||

| -216 | 1 1/8 | 1/8 | 1.109 | 0.012 | 0.139 | 0.004 | 28.17 | 0.30 | 3.53 | 0.10 | ||||||||||

| -217 | 1 3/16 | 1/8 | 1.171 | 0.012 | 0.139 | 0.004 | 29.74 | 0.30 | 3.53 | 0.10 | ||||||||||

| -218 | 1 1/4 | 1/8 | 1.234 | 0.012 | 0.139 | 0.004 | 31.34 | 0.30 | 3.53 | 0.10 | ||||||||||

| -219 | 1 5/16 | 1/8 | 1.296 | 0.012 | 0.139 | 0.004 | 32.92 | 0.30 | 3.53 | 0.10 | ||||||||||

| -220 | 1 3/8 | 1/8 | 1.359 | 0.012 | 0.139 | 0.004 | 34.52 | 0.30 | 3.53 | 0.10 | ||||||||||

| -221 | 1 7/16 | 1/8 | 1.421 | 0.012 | 0.139 | 0.004 | 36.09 | 0.30 | 3.53 | 0.10 | ||||||||||

| -222 | 1 1/2 | 1/8 | 1.484 | 0.015 | 0.139 | 0.004 | 37.69 | 0.38 | 3.53 | 0.10 | ||||||||||

| -223 | 1 5/8 | 1/8 | 1.609 | 0.015 | 0.139 | 0.004 | 40.87 | 0.38 | 3.53 | 0.10 | ||||||||||

| -224 | 1 3/4 | 1/8 | 1.734 | 0.015 | 0.139 | 0.004 | 44.04 | 0.38 | 3.53 | 0.10 | ||||||||||

| -225 | 1 7/8 | 1/8 | 1.859 | 0.018 | 0.139 | 0.004 | 47.22 | 0.46 | 3.53 | 0.10 | ||||||||||

| -226 | 2 | 1/8 | 1.984 | 0.018 | 0.139 | 0.004 | 50.39 | 0.46 | 3.53 | 0.10 | ||||||||||

| -227 | 2 1/8 | 1/8 | 2.109 | 0.018 | 0.139 | 0.004 | 53.57 | 0.46 | 3.53 | 0.10 | ||||||||||

| -228 | 2 1/4 | 1/8 | 2.234 | 0.020 | 0.139 | 0.004 | 56.74 | 0.51 | 3.53 | 0.10 | ||||||||||

| -229 | 2 3/8 | 1/8 | 2.359 | 0.020 | 0.139 | 0.004 | 59.92 | 0.51 | 3.53 | 0.10 | ||||||||||

| -230 | 2 1/2 | 1/8 | 2.484 | 0.020 | 0.139 | 0.004 | 63.09 | 0.51 | 3.53 | 0.10 | ||||||||||

| -231 | 2 5/8 | 1/8 | 2.609 | 0.020 | 0.139 | 0.004 | 66.27 | 0.51 | 3.53 | 0.10 | ||||||||||

| -232 | 2 3/4 | 1/8 | 2.734 | 0.024 | 0.139 | 0.004 | 69.44 | 0.61 | 3.53 | 0.10 | ||||||||||

| -233 | 2 7/8 | 1/8 | 2.859 | 0.024 | 0.139 | 0.004 | 72.62 | 0.61 | 3.53 | 0.10 | ||||||||||

| -234 | 3 | 1/8 | 2.984 | 0.024 | 0.139 | 0.004 | 75.79 | 0.61 | 3.53 | 0.10 | ||||||||||

| -235 | 3 1/8 | 1/8 | 3.109 | 0.024 | 0.139 | 0.004 | 78.97 | 0.61 | 3.53 | 0.10 | ||||||||||

| -236 | 3 1/4 | 1/8 | 3.234 | 0.024 | 0.139 | 0.004 | 82.14 | 0.61 | 3.53 | 0.10 | ||||||||||

| -237 | 3 3/8 | 1/8 | 3.359 | 0.024 | 0.139 | 0.004 | 85.32 | 0.61 | 3.53 | 0.10 | ||||||||||

| -238 | 3 1/2 | 1/8 | 3.484 | 0.024 | 0.139 | 0.004 | 88.49 | 0.61 | 3.53 | 0.10 | ||||||||||

| -239 | 3 5/8 | 1/8 | 3.609 | 0.028 | 0.139 | 0.004 | 91.67 | 0.71 | 3.53 | 0.10 | ||||||||||

| -240 | 3 3/4 | 1/8 | 3.734 | 0.028 | 0.139 | 0.004 | 94.84 | 0.71 | 3.53 | 0.10 | ||||||||||

| -241 | 3 7/8 | 1/8 | 3.859 | 0.028 | 0.139 | 0.004 | 98.02 | 0.71 | 3.53 | 0.10 | ||||||||||

| -242 | 4 | 1/8 | 3.984 | 0.028 | 0.139 | 0.004 | 101.19 | 0.71 | 3.53 | 0.10 | ||||||||||

| -243 | 4 1/8 | 1/8 | 4.109 | 0.028 | 0.139 | 0.004 | 104.37 | 0.71 | 3.53 | 0.10 | ||||||||||

| -244 | 4 1/4 | 1/8 | 4.234 | 0.030 | 0.139 | 0.004 | 107.54 | 0.76 | 3.53 | 0.10 | ||||||||||

| -245 | 4 3/8 | 1/8 | 4.359 | 0.030 | 0.139 | 0.004 | 110.72 | 0.76 | 3.53 | 0.10 | ||||||||||

| -246 | 4 1/2 | 1/8 | 4.484 | 0.030 | 0.139 | 0.004 | 113.89 | 0.76 | 3.53 | 0.10 | ||||||||||

| -247 | 4 5/8 | 1/8 | 4.609 | 0.030 | 0.139 | 0.004 | 117.07 | 0.76 | 3.53 | 0.10 | ||||||||||

| -248 | 4 3/4 | 1/8 | 4.734 | 0.030 | 0.139 | 0.004 | 120.24 | 0.76 | 3.53 | 0.10 | ||||||||||

| -249 | 4 7/8 | 1/8 | 4.859 | 0.035 | 0.139 | 0.004 | 123.42 | 0.89 | 3.53 | 0.10 | ||||||||||

| -250 | 5 | 1/8 | 4.984 | 0.035 | 0.139 | 0.004 | 126.59 | 0.89 | 3.53 | 0.10 | ||||||||||

| -251 | 5 1/8 | 1/8 | 5.109 | 0.035 | 0.139 | 0.004 | 129.77 | 0.89 | 3.53 | 0.10 | ||||||||||

| -252 | 5 1/4 | 1/8 | 5.234 | 0.035 | 0.139 | 0.004 | 132.94 | 0.89 | 3.53 | 0.10 | ||||||||||

| -253 | 5 3/8 | 1/8 | 5.359 | 0.035 | 0.139 | 0.004 | 136.12 | 0.89 | 3.53 | 0.10 | ||||||||||

| -254 | 5 1/2 | 1/8 | 5.484 | 0.035 | 0.139 | 0.004 | 139.29 | 0.89 | 3.53 | 0.10 | ||||||||||

| -255 | 5 5/8 | 1/8 | 5.609 | 0.035 | 0.139 | 0.004 | 142.47 | 0.89 | 3.53 | 0.10 | ||||||||||

| -256 | 5 3/4 | 1/8 | 5.734 | 0.035 | 0.139 | 0.004 | 145.64 | 0.89 | 3.53 | 0.10 | ||||||||||

| -257 | 5 7/8 | 1/8 | 5.859 | 0.035 | 0.139 | 0.004 | 148.82 | 0.89 | 3.53 | 0.10 | ||||||||||

| -258 | 6 | 1/8 | 5.984 | 0.035 | 0.139 | 0.004 | 151.99 | 0.89 | 3.53 | 0.10 | ||||||||||

| -259 | 6 1/4 | 1/8 | 6.234 | 0.040 | 0.139 | 0.004 | 158.34 | 1.02 | 3.53 | 0.10 | ||||||||||

| -260 | 6 1/2 | 1/8 | 6.484 | 0.040 | 0.139 | 0.004 | 164.69 | 1.02 | 3.53 | 0.10 | ||||||||||

| -261 | 6 3/4 | 1/8 | 6.734 | 0.040 | 0.139 | 0.004 | 171.04 | 1.02 | 3.53 | 0.10 | ||||||||||

| -262 | 7 | 1/8 | 6.984 | 0.040 | 0.139 | 0.004 | 177.39 | 1.02 | 3.53 | 0.10 | ||||||||||

| -263 | 7 1/4 | 1/8 | 7.234 | 0.045 | 0.139 | 0.004 | 183.74 | 1.14 | 3.53 | 0.10 | ||||||||||

| -264 | 7 1/2 | 1/8 | 7.484 | 0.045 | 0.139 | 0.004 | 190.09 | 1.14 | 3.53 | 0.10 | ||||||||||

| -265 | 7 3/4 | 1/8 | 7.734 | 0.045 | 0.139 | 0.004 | 196.44 | 1.14 | 3.53 | 0.10 | ||||||||||

| -266 | 8 | 1/8 | 7.984 | 0.045 | 0.139 | 0.004 | 202.79 | 1.14 | 3.53 | 0.10 | ||||||||||

| -267 | 8 1/4 | 1/8 | 8.234 | 0.050 | 0.139 | 0.004 | 209.14 | 1.27 | 3.53 | 0.10 | ||||||||||

| -268 | 8 1/2 | 1/8 | 8.484 | 0.050 | 0.139 | 0.004 | 215.49 | 1.27 | 3.53 | 0.10 | ||||||||||

| -269 | 8 3/4 | 1/8 | 8.734 | 0.050 | 0.139 | 0.004 | 221.84 | 1.27 | 3.53 | 0.10 | ||||||||||

| -270 | 9 | 1/8 | 8.984 | 0.050 | 0.139 | 0.004 | 228.19 | 1.27 | 3.53 | 0.10 | ||||||||||

| -271 | 9 1/4 | 1/8 | 9.234 | 0.055 | 0.139 | 0.004 | 234.54 | 1.40 | 3.53 | 0.10 | ||||||||||

| -272 | 9 1/2 | 1/8 | 9.484 | 0.055 | 0.139 | 0.004 | 240.89 | 1.40 | 3.53 | 0.10 | ||||||||||

| -273 | 9 3/4 | 1/8 | 9.734 | 0.055 | 0.139 | 0.004 | 247.24 | 1.40 | 3.53 | 0.10 | ||||||||||

| -274 | 10 | 1/8 | 9.984 | 0.055 | 0.139 | 0.004 | 253.59 | 1.40 | 3.53 | 0.10 | ||||||||||

| -275 | 10 1/2 | 1/8 | 10.484 | 0.055 | 0.139 | 0.004 | 266.29 | 1.40 | 3.53 | 0.10 | ||||||||||

| -276 | 11 | 1/8 | 10.984 | 0.065 | 0.139 | 0.004 | 278.99 | 1.65 | 3.53 | 0.10 | ||||||||||

| -277 | 11 1/2 | 1/8 | 11.484 | 0.065 | 0.139 | 0.004 | 291.69 | 1.65 | 3.53 | 0.10 | ||||||||||

| -278 | 12 | 1/8 | 11.984 | 0.065 | 0.139 | 0.004 | 304.39 | 1.65 | 3.53 | 0.10 | ||||||||||

| -279 | 13 | 1/8 | 12.984 | 0.065 | 0.139 | 0.004 | 329.79 | 1.65 | 3.53 | 0.10 | ||||||||||

| -280 | 14 | 1/8 | 13.984 | 0.065 | 0.139 | 0.004 | 355.19 | 1.65 | 3.53 | 0.10 | ||||||||||

| -281 | 15 | 1/8 | 14.984 | 0.065 | 0.139 | 0.004 | 380.59 | 1.65 | 3.53 | 0.10 | ||||||||||

| -282 | 16 | 1/8 | 15.955 | 0.075 | 0.139 | 0.004 | 405.26 | 1.91 | 3.53 | 0.10 | ||||||||||

| -283 | 17 | 1/8 | 16.955 | 0.080 | 0.139 | 0.004 | 430.66 | 2.03 | 3.53 | 0.10 | ||||||||||

| -284 | 18 | 1/8 | 17.955 | 0.085 | 0.139 | 0.004 | 456.06 | 2.16 | 3.53 | 0.10 | ||||||||||

| -309 | 7/16 | 3/16 | 0.412 | 0.005 | 0.210 | 0.005 | 10.46 | 0.13 | 5.33 | 0.13 | ||||||||||

| -310 | 1/2 | 3/16 | 0.475 | 0.005 | 0.210 | 0.005 | 12.07 | 0.13 | 5.33 | 0.13 | ||||||||||

| -311 | 9/16 | 3/16 | 0.537 | 0.007 | 0.210 | 0.005 | 13.64 | 0.18 | 5.33 | 0.13 | ||||||||||

| -312 | 5/8 | 3/16 | 0.600 | 0.009 | 0.210 | 0.005 | 15.24 | 0.23 | 5.33 | 0.13 | ||||||||||

| -313 | 11/16 | 3/16 | 0.662 | 0.009 | 0.210 | 0.005 | 16.81 | 0.23 | 5.33 | 0.13 | ||||||||||

| -314 | 3/4 | 3/16 | 0.725 | 0.010 | 0.210 | 0.005 | 18.42 | 0.25 | 5.33 | 0.13 | ||||||||||

| -315 | 13/16 | 3/16 | 0.787 | 0.010 | 0.210 | 0.005 | 19.99 | 0.25 | 5.33 | 0.13 | ||||||||||

| -316 | 7/8 | 3/16 | 0.850 | 0.010 | 0.210 | 0.005 | 21.59 | 0.25 | 5.33 | 0.13 | ||||||||||

| -317 | 15/16 | 3/16 | 0.912 | 0.010 | 0.210 | 0.005 | 23.16 | 0.25 | 5.33 | 0.13 | ||||||||||

| -318 | 1 | 3/16 | 0.975 | 0.010 | 0.210 | 0.005 | 24.77 | 0.25 | 5.33 | 0.13 | ||||||||||

| -319 | 1 1/16 | 3/16 | 1.037 | 0.010 | 0.210 | 0.005 | 26.34 | 0.25 | 5.33 | 0.13 | ||||||||||

| -320 | 1 1/8 | 3/16 | 1.100 | 0.012 | 0.210 | 0.005 | 27.94 | 0.30 | 5.33 | 0.13 | ||||||||||

| -321 | 1 3/16 | 3/16 | 1.162 | 0.012 | 0.210 | 0.005 | 29.51 | 0.30 | 5.33 | 0.13 | ||||||||||

| -322 | 1 1/4 | 3/16 | 1.225 | 0.012 | 0.210 | 0.005 | 31.12 | 0.30 | 5.33 | 0.13 | ||||||||||

| -323 | 1 5/16 | 3/16 | 1.287 | 0.012 | 0.210 | 0.005 | 32.69 | 0.30 | 5.33 | 0.13 | ||||||||||

| -324 | 1 3/8 | 3/16 | 1.350 | 0.012 | 0.210 | 0.005 | 34.29 | 0.30 | 5.33 | 0.13 | ||||||||||

| -325 | 1 1/2 | 3/16 | 1.475 | 0.015 | 0.210 | 0.005 | 37.47 | 0.38 | 5.33 | 0.13 | ||||||||||

| -326 | 1 5/8 | 3/16 | 1.600 | 0.015 | 0.210 | 0.005 | 40.64 | 0.38 | 5.33 | 0.13 | ||||||||||

| -327 | 1 3/4 | 3/16 | 1.725 | 0.015 | 0.210 | 0.005 | 43.82 | 0.38 | 5.33 | 0.13 | ||||||||||

| -328 | 1 7/8 | 3/16 | 1.850 | 0.015 | 0.210 | 0.005 | 46.99 | 0.38 | 5.33 | 0.13 | ||||||||||

| -329 | 2 | 3/16 | 1.975 | 0.018 | 0.210 | 0.005 | 50.17 | 0.46 | 5.33 | 0.13 | ||||||||||

| -330 | 2 1/8 | 3/16 | 2.100 | 0.018 | 0.210 | 0.005 | 53.34 | 0.46 | 5.33 | 0.13 | ||||||||||

| -331 | 2 1/4 | 3/16 | 2.225 | 0.018 | 0.210 | 0.005 | 56.52 | 0.46 | 5.33 | 0.13 | ||||||||||

| -332 | 2 3/8 | 3/16 | 2.350 | 0.018 | 0.210 | 0.005 | 59.69 | 0.46 | 5.33 | 0.13 | ||||||||||

| -333 | 2 1/2 | 3/16 | 2.475 | 0.020 | 0.210 | 0.005 | 62.87 | 0.51 | 5.33 | 0.13 | ||||||||||

| -334 | 2 5/8 | 3/16 | 2.600 | 0.020 | 0.210 | 0.005 | 66.04 | 0.51 | 5.33 | 0.13 | ||||||||||

| -335 | 2 3/4 | 3/16 | 2.725 | 0.020 | 0.210 | 0.005 | 69.22 | 0.51 | 5.33 | 0.13 | ||||||||||

| -336 | 2 7/8 | 3/16 | 2.850 | 0.020 | 0.210 | 0.005 | 72.39 | 0.51 | 5.33 | 0.13 | ||||||||||

| -337 | 3 | 3/16 | 2.975 | 0.024 | 0.210 | 0.005 | 75.57 | 0.61 | 5.33 | 0.13 | ||||||||||

| -338 | 3 1/8 | 3/16 | 3.100 | 0.024 | 0.210 | 0.005 | 78.74 | 0.61 | 5.33 | 0.13 | ||||||||||

| -339 | 3 1/4 | 3/16 | 3.225 | 0.024 | 0.210 | 0.005 | 81.92 | 0.61 | 5.33 | 0.13 | ||||||||||

| -340 | 3 3/8 | 3/16 | 3.350 | 0.024 | 0.210 | 0.005 | 85.09 | 0.61 | 5.33 | 0.13 | ||||||||||

| -341 | 3 1/2 | 3/16 | 3.475 | 0.024 | 0.210 | 0.005 | 88.27 | 0.61 | 5.33 | 0.13 | ||||||||||

| -342 | 3 5/8 | 3/16 | 3.600 | 0.028 | 0.210 | 0.005 | 91.44 | 0.71 | 5.33 | 0.13 | ||||||||||

| -343 | 3 3/4 | 3/16 | 3.725 | 0.028 | 0.210 | 0.005 | 94.62 | 0.71 | 5.33 | 0.13 | ||||||||||

| -344 | 3 7/8 | 3/16 | 3.850 | 0.028 | 0.210 | 0.005 | 97.79 | 0.71 | 5.33 | 0.13 | ||||||||||

| -345 | 4 | 3/16 | 3.975 | 0.028 | 0.210 | 0.005 | 100.97 | 0.71 | 5.33 | 0.13 | ||||||||||

| -346 | 4 1/8 | 3/16 | 4.100 | 0.028 | 0.210 | 0.005 | 104.14 | 0.71 | 5.33 | 0.13 | ||||||||||

| -347 | 4 1/4 | 3/16 | 4.225 | 0.030 | 0.210 | 0.005 | 107.32 | 0.76 | 5.33 | 0.13 | ||||||||||

| -348 | 4 3/8 | 3/16 | 4.350 | 0.030 | 0.210 | 0.005 | 110.49 | 0.76 | 5.33 | 0.13 | ||||||||||

| -349 | 4 1/2 | 3/16 | 4.475 | 0.030 | 0.210 | 0.005 | 113.67 | 0.76 | 5.33 | 0.13 | ||||||||||

| -350 | 4 5/8 | 3/16 | 4.600 | 0.030 | 0.210 | 0.005 | 116.84 | 0.76 | 5.33 | 0.13 | ||||||||||

| -351 | 4 3/4 | 3/16 | 4.725 | 0.030 | 0.210 | 0.005 | 120.02 | 0.76 | 5.33 | 0.13 | ||||||||||

| -352 | 4 7/8 | 3/16 | 4.850 | 0.030 | 0.210 | 0.005 | 123.19 | 0.76 | 5.33 | 0.13 | ||||||||||

| -353 | 5 | 3/16 | 4.975 | 0.037 | 0.210 | 0.005 | 126.37 | 0.94 | 5.33 | 0.13 | ||||||||||

| -354 | 5 1/8 | 3/16 | 5.100 | 0.037 | 0.210 | 0.005 | 129.54 | 0.94 | 5.33 | 0.13 | ||||||||||

| -355 | 5 1/4 | 3/16 | 5.225 | 0.037 | 0.210 | 0.005 | 132.72 | 0.94 | 5.33 | 0.13 | ||||||||||

| -356 | 5 3/8 | 3/16 | 5.350 | 0.037 | 0.210 | 0.005 | 135.89 | 0.94 | 5.33 | 0.13 | ||||||||||

| -357 | 5 1/2 | 3/16 | 5.475 | 0.037 | 0.210 | 0.005 | 139.07 | 0.94 | 5.33 | 0.13 | ||||||||||

| -358 | 5 5/8 | 3/16 | 5.600 | 0.037 | 0.210 | 0.005 | 142.24 | 0.94 | 5.33 | 0.13 | ||||||||||

| -359 | 5 3/4 | 3/16 | 5.725 | 0.037 | 0.210 | 0.005 | 145.42 | 0.94 | 5.33 | 0.13 | ||||||||||

| -360 | 5 7/8 | 3/16 | 5.850 | 0.037 | 0.210 | 0.005 | 148.59 | 0.94 | 5.33 | 0.13 | ||||||||||

| -361 | 6 | 3/16 | 5.975 | 0.037 | 0.210 | 0.005 | 151.77 | 0.94 | 5.33 | 0.13 | ||||||||||

| -362 | 6 1/4 | 3/16 | 6.225 | 0.040 | 0.210 | 0.005 | 158.12 | 1.02 | 5.33 | 0.13 | ||||||||||

| -363 | 6 1/2 | 3/16 | 6.475 | 0.040 | 0.210 | 0.005 | 164.47 | 1.02 | 5.33 | 0.13 | ||||||||||

| -364 | 6 3/4 | 3/16 | 6.725 | 0.040 | 0.210 | 0.005 | 170.82 | 1.02 | 5.33 | 0.13 | ||||||||||

| -365 | 7 | 3/16 | 6.975 | 0.040 | 0.210 | 0.005 | 177.17 | 1.02 | 5.33 | 0.13 | ||||||||||

| -366 | 7 1/4 | 3/16 | 7.225 | 0.045 | 0.210 | 0.005 | 183.52 | 1.14 | 5.33 | 0.13 | ||||||||||

| -367 | 7 1/2 | 3/16 | 7.475 | 0.045 | 0.210 | 0.005 | 189.87 | 1.14 | 5.33 | 0.13 | ||||||||||

| -368 | 7 3/4 | 3/16 | 7.725 | 0.045 | 0.210 | 0.005 | 196.22 | 1.14 | 5.33 | 0.13 | ||||||||||

| -369 | 8 | 3/16 | 7.975 | 0.045 | 0.210 | 0.005 | 202.57 | 1.14 | 5.33 | 0.13 | ||||||||||

| -370 | 8 1/4 | 3/16 | 8.225 | 0.050 | 0.210 | 0.005 | 208.92 | 1.27 | 5.33 | 0.13 | ||||||||||

| -371 | 8 1/2 | 3/16 | 8.475 | 0.050 | 0.210 | 0.005 | 215.27 | 1.27 | 5.33 | 0.13 | ||||||||||

| -372 | 8 3/4 | 3/16 | 8.725 | 0.050 | 0.210 | 0.005 | 221.62 | 1.27 | 5.33 | 0.13 | ||||||||||

| -373 | 9 | 3/16 | 8.975 | 0.050 | 0.210 | 0.005 | 227.97 | 1.27 | 5.33 | 0.13 | ||||||||||

| -374 | 9 1/4 | 3/16 | 9.225 | 0.055 | 0.210 | 0.005 | 234.32 | 1.40 | 5.33 | 0.13 | ||||||||||

| -375 | 9 1/2 | 3/16 | 9.475 | 0.055 | 0.210 | 0.005 | 240.67 | 1.40 | 5.33 | 0.13 | ||||||||||

| -376 | 9 3/4 | 3/16 | 9.725 | 0.055 | 0.210 | 0.005 | 247.02 | 1.40 | 5.33 | 0.13 | ||||||||||

| -377 | 10 | 3/16 | 9.975 | 0.055 | 0.210 | 0.005 | 253.37 | 1.40 | 5.33 | 0.13 | ||||||||||

| -378 | 10 1/2 | 3/16 | 10.475 | 0.060 | 0.210 | 0.005 | 266.07 | 1.52 | 5.33 | 0.13 | ||||||||||

| -379 | 11 | 3/16 | 10.975 | 0.060 | 0.210 | 0.005 | 278.77 | 1.52 | 5.33 | 0.13 | ||||||||||

| -380 | 11 1/2 | 3/16 | 11.475 | 0.065 | 0.210 | 0.005 | 291.47 | 1.65 | 5.33 | 0.13 | ||||||||||

| -381 | 12 | 3/16 | 11.975 | 0.065 | 0.210 | 0.005 | 304.17 | 1.65 | 5.33 | 0.13 | ||||||||||

| -382 | 13 | 3/16 | 12.975 | 0.065 | 0.210 | 0.005 | 329.57 | 1.65 | 5.33 | 0.13 | ||||||||||

| -383 | 14 | 3/16 | 13.975 | 0.070 | 0.210 | 0.005 | 354.97 | 1.78 | 5.33 | 0.13 | ||||||||||

| -384 | 15 | 3/16 | 14.975 | 0.070 | 0.210 | 0.005 | 380.37 | 1.78 | 5.33 | 0.13 | ||||||||||

| -385 | 16 | 3/16 | 15.955 | 0.075 | 0.210 | 0.005 | 405.26 | 1.91 | 5.33 | 0.13 | ||||||||||

| -386 | 17 | 3/16 | 16.955 | 0.080 | 0.210 | 0.005 | 430.66 | 2.03 | 5.33 | 0.13 | ||||||||||

| -387 | 18 | 3/16 | 17.955 | 0.085 | 0.210 | 0.005 | 456.06 | 2.16 | 5.33 | 0.13 | ||||||||||

| -388 | 19 | 3/16 | 18.955 | 0.090 | 0.210 | 0.005 | 481.45 | 2.29 | 5.33 | 0.13 | ||||||||||

| -389 | 20 | 3/16 | 19.955 | 0.095 | 0.210 | 0.005 | 506.85 | 2.41 | 5.33 | 0.13 | ||||||||||

| -390 | 21 | 3/16 | 20.955 | 0.095 | 0.210 | 0.005 | 532.25 | 2.41 | 5.33 | 0.13 | ||||||||||

| -391 | 22 | 3/16 | 21.955 | 0.100 | 0.210 | 0.005 | 557.65 | 2.54 | 5.33 | 0.13 | ||||||||||

| -392 | 23 | 3/16 | 22.940 | 0.105 | 0.210 | 0.005 | 582.68 | 2.67 | 5.33 | 0.13 | ||||||||||

| -393 | 24 | 3/16 | 23.940 | 0.110 | 0.210 | 0.005 | 608.08 | 2.79 | 5.33 | 0.13 | ||||||||||

| -394 | 25 | 3/16 | 24.940 | 0.115 | 0.210 | 0.005 | 633.48 | 2.92 | 5.33 | 0.13 | ||||||||||

| -395 | 26 | 3/16 | 25.940 | 0.120 | 0.210 | 0.005 | 658.88 | 3.05 | 5.33 | 0.13 | ||||||||||

| -425 | 4 1/2 | 1/4 | 4.475 | 0.033 | 0.275 | 0.006 | 113.67 | 0.84 | 6.99 | 0.15 | ||||||||||

| -426 | 4 5/8 | 1/4 | 4.600 | 0.033 | 0.275 | 0.006 | 116.84 | 0.84 | 6.99 | 0.15 | ||||||||||

| -427 | 4 3/4 | 1/4 | 4.725 | 0.033 | 0.275 | 0.006 | 120.02 | 0.84 | 6.99 | 0.15 | ||||||||||

| -428 | 4 7/8 | 1/4 | 4.850 | 0.033 | 0.275 | 0.006 | 123.19 | 0.84 | 6.99 | 0.15 | ||||||||||

| -429 | 5 | 1/4 | 4.975 | 0.037 | 0.275 | 0.006 | 126.37 | 0.94 | 6.99 | 0.15 | ||||||||||

| -430 | 5 1/8 | 1/4 | 5.100 | 0.037 | 0.275 | 0.006 | 129.54 | 0.94 | 6.99 | 0.15 | ||||||||||

| -431 | 5 1/4 | 1/4 | 5.225 | 0.037 | 0.275 | 0.006 | 132.72 | 0.94 | 6.99 | 0.15 | ||||||||||

| -432 | 5 3/8 | 1/4 | 5.350 | 0.037 | 0.275 | 0.006 | 135.89 | 0.94 | 6.99 | 0.15 | ||||||||||

| -433 | 5 1/2 | 1/4 | 5.475 | 0.037 | 0.275 | 0.006 | 139.07 | 0.94 | 6.99 | 0.15 | ||||||||||

| -434 | 5 5/8 | 1/4 | 5.600 | 0.037 | 0.275 | 0.006 | 142.24 | 0.94 | 6.99 | 0.15 | ||||||||||

| -435 | 5 3/4 | 1/4 | 5.725 | 0.037 | 0.275 | 0.006 | 145.42 | 0.94 | 6.99 | 0.15 | ||||||||||

| -436 | 5 7/8 | 1/4 | 5.850 | 0.037 | 0.275 | 0.006 | 148.59 | 0.94 | 6.99 | 0.15 | ||||||||||

| -437 | 6 | 1/4 | 5.975 | 0.037 | 0.275 | 0.006 | 151.77 | 0.94 | 6.99 | 0.15 | ||||||||||

| -438 | 6 1/4 | 1/4 | 6.225 | 0.040 | 0.275 | 0.006 | 158.12 | 1.02 | 6.99 | 0.15 | ||||||||||

| -439 | 6 1/2 | 1/4 | 6.475 | 0.040 | 0.275 | 0.006 | 164.47 | 1.02 | 6.99 | 0.15 | ||||||||||

| -440 | 6 3/4 | 1/4 | 6.725 | 0.040 | 0.275 | 0.006 | 170.82 | 1.02 | 6.99 | 0.15 | ||||||||||

| -441 | 7 | 1/4 | 6.975 | 0.040 | 0.275 | 0.006 | 177.17 | 1.02 | 6.99 | 0.15 | ||||||||||

| -442 | 7 1/4 | 1/4 | 7.225 | 0.045 | 0.275 | 0.006 | 183.52 | 1.14 | 6.99 | 0.15 | ||||||||||

| -443 | 7 1/2 | 1/4 | 7.475 | 0.045 | 0.275 | 0.006 | 189.87 | 1.14 | 6.99 | 0.15 | ||||||||||

| -444 | 7 3/4 | 1/4 | 7.725 | 0.045 | 0.275 | 0.006 | 196.22 | 1.14 | 6.99 | 0.15 | ||||||||||

| -445 | 8 | 1/4 | 7.975 | 0.045 | 0.275 | 0.006 | 202.57 | 1.14 | 6.99 | 0.15 | ||||||||||

| -446 | 8 1/2 | 1/4 | 8.475 | 0.055 | 0.275 | 0.006 | 215.27 | 1.40 | 6.99 | 0.15 | ||||||||||

| -447 | 9 | 1/4 | 8.975 | 0.055 | 0.275 | 0.006 | 227.97 | 1.40 | 6.99 | 0.15 | ||||||||||

| -448 | 9 1/2 | 1/4 | 9.475 | 0.055 | 0.275 | 0.006 | 240.67 | 1.40 | 6.99 | 0.15 | ||||||||||

| -449 | 10 | 1/4 | 9.975 | 0.055 | 0.275 | 0.006 | 253.37 | 1.40 | 6.99 | 0.15 | ||||||||||

| -450 | 10 1/2 | 1/4 | 10.475 | 0.060 | 0.275 | 0.006 | 266.07 | 1.52 | 6.99 | 0.15 | ||||||||||

| -451 | 11 | 1/4 | 10.975 | 0.060 | 0.275 | 0.006 | 278.77 | 1.52 | 6.99 | 0.15 | ||||||||||

| -452 | 11 1/2 | 1/4 | 11.475 | 0.060 | 0.275 | 0.006 | 291.47 | 1.52 | 6.99 | 0.15 | ||||||||||

| -453 | 12 | 1/4 | 11.975 | 0.060 | 0.275 | 0.006 | 304.17 | 1.52 | 6.99 | 0.15 | ||||||||||

| -454 | 12 1/2 | 1/4 | 12.475 | 0.060 | 0.275 | 0.006 | 316.87 | 1.52 | 6.99 | 0.15 | ||||||||||

| -455 | 13 | 1/4 | 12.975 | 0.060 | 0.275 | 0.006 | 329.57 | 1.52 | 6.99 | 0.15 | ||||||||||

| -456 | 13 1/2 | 1/4 | 13.475 | 0.070 | 0.275 | 0.006 | 342.27 | 1.78 | 6.99 | 0.15 | ||||||||||

| -457 | 14 | 1/4 | 13.975 | 0.070 | 0.275 | 0.006 | 354.97 | 1.78 | 6.99 | 0.15 | ||||||||||

| -458 | 14 1/2 | 1/4 | 14.475 | 0.070 | 0.275 | 0.006 | 367.67 | 1.78 | 6.99 | 0.15 | ||||||||||

| -459 | 15 | 1/4 | 14.975 | 0.070 | 0.275 | 0.006 | 380.37 | 1.78 | 6.99 | 0.15 | ||||||||||

| -460 | 15 1/2 | 1/4 | 15.475 | 0.070 | 0.275 | 0.006 | 393.07 | 1.78 | 6.99 | 0.15 | ||||||||||

| -461 | 16 | 1/4 | 15.955 | 0.075 | 0.275 | 0.006 | 405.26 | 1.91 | 6.99 | 0.15 | ||||||||||

| -462 | 16 1/2 | 1/4 | 16.455 | 0.075 | 0.275 | 0.006 | 417.96 | 1.91 | 6.99 | 0.15 | ||||||||||

| -463 | 17 | 1/4 | 16.955 | 0.080 | 0.275 | 0.006 | 430.66 | 2.03 | 6.99 | 0.15 | ||||||||||

| -464 | 17 1/2 | 1/4 | 17.455 | 0.085 | 0.275 | 0.006 | 443.36 | 2.16 | 6.99 | 0.15 | ||||||||||

| -465 | 18 | 1/4 | 17.955 | 0.085 | 0.275 | 0.006 | 456.06 | 2.16 | 6.99 | 0.15 | ||||||||||

| -466 | 18 1/2 | 1/4 | 18.455 | 0.085 | 0.275 | 0.006 | 468.76 | 2.16 | 6.99 | 0.15 | ||||||||||

| -467 | 19 | 1/4 | 18.955 | 0.090 | 0.275 | 0.006 | 481.46 | 2.29 | 6.99 | 0.15 | ||||||||||

| -468 | 19 1/2 | 1/4 | 19.455 | 0.090 | 0.275 | 0.006 | 494.16 | 2.29 | 6.99 | 0.15 | ||||||||||

| -469 | 20 | 1/4 | 19.955 | 0.095 | 0.275 | 0.006 | 506.86 | 2.41 | 6.99 | 0.15 | ||||||||||

| -470 | 21 | 1/4 | 20.955 | 0.095 | 0.275 | 0.006 | 532.26 | 2.41 | 6.99 | 0.15 | ||||||||||

| -471 | 22 | 1/4 | 21.955 | 0.100 | 0.275 | 0.006 | 557.66 | 2.54 | 6.99 | 0.15 | ||||||||||

| -472 | 23 | 1/4 | 22.940 | 0.105 | 0.275 | 0.006 | 582.68 | 2.67 | 6.99 | 0.15 | ||||||||||

| -473 | 24 | 1/4 | 23.940 | 0.110 | 0.275 | 0.006 | 608.08 | 2.79 | 6.99 | 0.15 | ||||||||||

| -474 | 25 | 1/4 | 24.940 | 0.115 | 0.275 | 0.006 | 633.48 | 2.92 | 6.99 | 0.15 | ||||||||||

| -475 | 26 | 1/4 | 25.940 | 0.120 | 0.275 | 0.006 | 658.88 | 3.05 | 6.99 | 0.15 | ||||||||||

| Ubukhulu be-AS568 | Isazisi segama | I-ID yeMilinganiso ngee-intshi | ±ID | Imilinganiselo CS ngee-intshi | ±CS | I-ID yeMilinganiso kwi-mm | ±ID | Imilinganiselo CS kwi mm | ± C/S | |||||||||||

| -901 | 3/32 | 0.185 | 0.005 | 0.056 | 0.003 | 4.70 | 0.13 | 1.42 | 0.08 | |||||||||||

| -902 | 1/8 | 0.239 | 0.005 | 0.064 | 0.003 | 6.07 | 0.13 | 1.63 | 0.08 | |||||||||||

| -903 | 3/16 | 0.301 | 0.005 | 0.064 | 0.003 | 7.65 | 0.13 | 1.63 | 0.08 | |||||||||||

| -904 | 1/4 | 0.351 | 0.005 | 0.072 | 0.003 | 8.92 | 0.13 | 1.83 | 0.08 | |||||||||||

| -905 | 5/16 | 0.414 | 0.005 | 0.072 | 0.003 | 10.52 | 0.13 | 1.83 | 0.08 | |||||||||||

| -906 | 3/8 | 0.468 | 0.005 | 0.078 | 0.003 | 11.89 | 0.13 | 1.98 | 0.08 | |||||||||||

| -907 | 7/16 | 0.530 | 0.007 | 0.082 | 0.003 | 13.46 | 0.18 | 2.08 | 0.08 | |||||||||||

| -908 | 1/2 | 0.644 | 0.009 | 0.087 | 0.003 | 16.36 | 0.23 | 2.21 | 0.08 | |||||||||||

| -909 | 9/16 | 0.706 | 0.009 | 0.097 | 0.003 | 17.93 | 0.23 | 2.46 | 0.08 | |||||||||||

| -910 | 5/8 | 0.755 | 0.009 | 0.097 | 0.003 | 19.18 | 0.23 | 2.46 | 0.08 | |||||||||||

| -911 | 11/16 | 0.863 | 0.009 | 0.116 | 0.004 | 21.92 | 0.23 | 2.95 | 0.10 | |||||||||||

| -912 | 3/4 | 0.924 | 0.009 | 0.116 | 0.004 | 23.47 | 0.23 | 2.95 | 0.10 | |||||||||||

| -913 | 13/16 | 0.986 | 0.010 | 0.116 | 0.004 | 25.04 | 0.25 | 2.95 | 0.10 | |||||||||||

| -914 | 7/8 | 1.047 | 0.010 | 0.116 | 0.004 | 26.59 | 0.25 | 2.95 | 0.10 | |||||||||||

| -916 | 1 | 1.171 | 0.010 | 0.116 | 0.004 | 29.74 | 0.25 | 2.95 | 0.10 | |||||||||||

| -918 | 1 1/8 | 1.355 | 0.012 | 0.116 | 0.004 | 34.42 | 0.30 | 2.95 | 0.10 | |||||||||||

| -920 | 1 1/4 | 1.475 | 0.014 | 0.118 | 0.004 | 37.47 | 0.36 | 3.00 | 0.10 | |||||||||||

| -924 | 1 1/2 | 1.720 | 0.014 | 0.118 | 0.004 | 43.69 | 0.36 | 3.00 | 0.10 | |||||||||||

| -928 | 1 3/4 | 2.090 | 0.018 | 0.118 | 0.004 | 53.09 | 0.46 | 3.00 | 0.10 | |||||||||||

| -932 | 2 | 2.337 | 0.018 | 0.118 | 0.004 | 59.36 | 0.46 | 3.00 | 0.10 | |||||||||||

Okwesibini -Izinga loxinzelelo kunye nexabiso lokwelula ngenxaiioringi

I-O-ring yitywina eqhelekileyo ekhutshiweyo. Umlinganiselo wokunyanzeliswa kunye nokwelula kwe-diameter ye-cross-sectional ye-O-ring yimixholo ephambili yoyilo lokutywinwa, olubaluleke kakhulu ekusebenzeni kokutywinwa kunye nobomi benkonzo. Isiphumo esihle sokutywinwa kwe-O-ring ubukhulu becala sixhomekeke ekulungelelaniseni okuchanekileyo kobukhulu be-O-ring kunye nobukhulu be-groove, ukwenza ukunyanzeliswa okufanelekileyo kunye nomthamo wokwelula umsesane wokutywina.

1. Izinga loxinzelelo

Izinga loxinzelelo lwe-W lidla ngokuchazwa ngolu hlobo lulandelayo:

W=(d0 h)/d0 × 100%

Kwifomula, i-d0- i-diameter ye-cross-sectional ye-O-ring kwi-free state (mm);

H - Umgama phakathi komzantsi we-O-ring groove kunye nomgangatho otywiniweyo (ubunzulu begroove), oko kukuthi ukuphakama kwecandelo le-O-ring emva koxinzelelo (mm)

2.Xa ukhetha umlinganiselo woxinzelelo lwe-O-ring, le miba mithathu ilandelayo kufuneka ithathelwe ingqalelo:

(1). Kufuneka kubekho indawo yoqhagamshelwano eyaneleyo yokutywina;(2). Zama ukunciphisa amandla okukhuhlana;(3). Zama ukuphepha deformation esisigxina.

Akunzima ukubona kwezi zinto zingasentla ukuba kukho ukuphikisana phakathi kwazo. Izinga loxinzelelo oluphezulu lunokufumana uxinzelelo oluphezulu lokunxibelelana, kodwa isantya soxinzelelo esigqithisileyo ngokungathandabuzekiyo sonyusa i-sliding friction kunye ne-deformation esisigxina. Ukuba izinga loxinzelelo lincinci kakhulu, linokuba ngenxa yempazamo ye-coaxiality kunye ne-O-ring yempazamo ye-groove yokutywina engahlangabezani neemfuno, okukhokelela ekunyamaleni kwexabiso elithile loxinzelelo kunye nokubangela ukuvuza. Ngoko ke, xa ukhetha umlinganiselo wokunyanzeliswa kwe-O-ring, kuyimfuneko ukulinganisa izinto ezahlukeneyo. Ngokubanzi, izinga loxinzelelo lwezitywina ezimileyo likhulu kunelo lamatywina aguquguqukayo, kodwa ixabiso lawo eligqithisileyo kufuneka libe ngaphantsi kwama-25%. Ngaphandle koko, ukunyanzeliswa kwengcinezelo kuya kuphumla kakhulu kunye nokuguqulwa okugqithisileyo okusisigxina kuya kwenzeka, ngokukodwa kwiimeko zokusebenza eziphezulu. Ukutywinwa kwe-Static kunokohlulwa kube ukutywinwa kwe-radial kunye nokutywinwa kwe-axial; Umsantsa wokuvuza kwamatywina e-radial (okanye i-cylindrical static seals) yi-gap ye-radial, ngelixa i-gap yokuvuza kwee-axial seals (okanye i-planar static seals) yi-axial gap. Ukutywinwa kwe-Axial kwahlula kwiimeko ezimbini ngokusekelwe ekubeni i-pressure medium ithatha i-diameter yangaphakathi okanye i-diameter yangaphandle ye-O-ring: uxinzelelo lwangaphakathi kunye noxinzelelo lwangaphandle. Ukunyuka koxinzelelo lwangaphakathi kukhokelela ekwandiseni, ngelixa uxinzelelo lwangaphandle lunciphisa ukunweba kokuqala kwe-O-ring. Iindlela ezahlukeneyo zokutywina ezimileyo ezikhankanywe ngasentla zineendlela ezahlukeneyo zesenzo sendlela yokutywina kwi-O-ring, ngoko ke uyilo loxinzelelo lwangaphambili nalo lwahlukile. Kumatywina aguquguqukayo, kuyafuneka ukwahlula phakathi kwezitywina ezihambayo eziphindaphindanayo kunye nezitywina ezijikelezayo.

(2). Ukutywinwa okuzinzileyo: Njengezixhobo zokutywina eziphinda-phindaneyo, izixhobo zokutywina ezimileyo zecylindrical zihlala zithatha W=10% ukuya kwi-15%; Isixhobo sokutywina esimileyo esisicaba sithatha W = 15% ~ 30%.Ukutywinwa okuguquguqukayo, kunokwahlulwa ngokweemeko ezintathu; Isindululo sokubuyiselana sithathwa ngokubanzi njenge-W=10% ukuya kwi-15%. Xa ukhetha umlinganiselo wokunyanzeliswa kwezitywina ze-rotary motion, umphumo wokushisa we-Joule kufuneka uqwalaselwe. Ngokuqhelekileyo, i-diameter yangaphakathi ye-O-ring esetyenziselwa ukuhamba kwe-rotary yi-3% -5% enkulu kunobubanzi be-shaft, kunye nomlinganiselo woxinzelelo we-diameter yangaphandle ngu-W = 3% -8%. Kwimidlalo ye-friction ephantsi, ii-O-rings zikhethwa ngokubanzi kunye nomlinganiselo omncinci wokunciphisa i-W = 5% -8% ukwenzela ukunciphisa ukuxhatshazwa. Ukongezelela, ukwandiswa kwezinto zerabha ezibangelwa yi-medium kunye neqondo lokushisa kufuneka kuqwalaselwe. Ngokuqhelekileyo, ngaphaya kwe-deformation yoxinzelelo olunikiweyo, umlinganiselo ophezulu ovumelekileyo wokwandisa yi-15%. Ukugqithisa olu luhlu lubonisa ukuba ukhetho lwezinto eziphathekayo alufanelekanga, kwaye i-O-rings yezinye izinto kufuneka isetyenziswe endaweni yoko, okanye i-compression deformation rate kufuneka ilungiswe.

(3)Imali eyoluliweyo,Emva kokufakwa kwigroove yokutywina, i-O-ring inomlinganiselo othile wokolula. Njengomlinganiselo wokunyanzeliswa, inani lokwelula nalo linempembelelo enkulu ekusebenzeni kokutywinwa kunye nobomi benkonzo ye-O-ring. Isixa esikhulu sokwelula akwenzi nje kube nzima ukufaka i-O-ring, kodwa kunciphisa izinga loxinzelelo ngenxa yeenguqu kwi-diameter ye-cross-sectional d0, ekhokelela ekuvuzeni. Isixa esolulayo a singabonakaliswa ngolu hlobo lulandelayo:α= (d+d0)/(d1+d0) Kwifomula, d – i-shaft diameter (mm); D1– I-diameter yangaphakathi ye-O-ring (mm) .Uluhlu lwexabiso lokwelula luyi-1% -5%. Amaxabiso acetyiswayo kwixabiso lokwelula kwe-O-ring anikwe kwitheyibhile. Umlinganiselo wokwelula we-O-ring unokukhethwa ngokobukhulu be-shaft diameter ngokomda wokukhethwa kwetafile. Uluhlu oluphambili lomlinganiselo wokunyanzeliswa kunye nexabiso lokwelula kwi-O-ring

Okwesithathu-ubudlelwane phakathi kwe-diameter yangaphakathi (ID), i-diameter yangaphandle (OD), kunye ne-wire diameter (C / S) ye-O-ring.

OD=ID+C/S*2 Enje : ID=3MM C/S=1MM OD=3MM+1*2=5MM

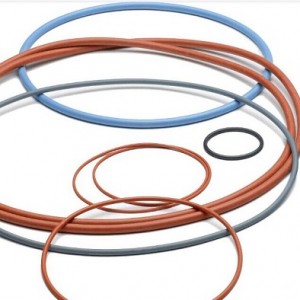

Okwesine-Izinto ezisetyenziswa ngokuqhelekileyo kwimveliso ye-O-rings

- NBR :NBR O-RING

inokumelana ne-oli okugqwesileyo, ukumelana nobushushu be-benzene, ukumelana nobushushu, kunye neempawu zomzimba nezomatshini, kwaye yenye yezinto ezixhaphakileyo zokwenziwa kweemveliso zerabha ezixhathisa i-oyile. Isetyenziswa kakhulu xa kusenziwa iigaskets ezixhathisa ioyile, iigaskets, imibhobho yerabha, iibhokisi zeposi zenqwelomoya, ukupakishwa okubhetyebhetye, ukuprinta kunye nokudaya iirola zerabha, izixhobo zentambo, kunye nezinto zokuncamathelisa.

- EPDM:EPDM O-RING

kunye neempawu ezibalaseleyo zoomatshini, ukuxhathisa imichiza, kunye nokuxhathisa ubushushu, ngelixa ikwabonisa ukuxhathisa okunamandla kwemozulu. I-Ethylene propylene diene monomer (EPDM) ibonisa iipropati ezibalaseleyo malunga nokumelana ne-ozone, ukuxhathisa ubushushu, ukuxhathisa imozulu, kunye nokuthamba okuphantsi, okwenza ukuba ifanelekele izicelo ezixhathisa i-ozone, ukumelana nemozulu, kunye nokumelana ne-UV. Nangona kunjalo, ngenxa yeempawu zayo zesakhiwo, ukuncitshiswa komlilo, ukuxhathisa kweoli, kunye nokunamathela kwerabha ye-EPDM ayilulanga. Nangona kunjalo, olu hlobo lwerabha lunekhonkco elingundoqo elihluthisiweyo kwaye linokudityaniswa nezinye izinto zokuphucula ukusebenza ngokufunda amandla kunye nobuthathaka bomnye.

- VMQ(SILICONE):ISILICONE O-RING

ngobushushu kunye nokumelana neoli. Irabha yeSilicone inokumelana nobushushu obuphantsi kwaye ingasebenza ngokubanzi ku -55 ℃. Emva kokuqaliswa kwephenyl, inokufikelela ku -73 ℃. Ukumelana nobushushu berabha ye-silicone nayo ibalasele, kwaye inokusebenza ixesha elide kwi-180 ℃. Iyakwazi ukumelana neeveki ezininzi okanye ngaphezulu kokunwebeka nangaphezulu kancinci kwe-200 ℃, kwaye ngoko nangoko inokumelana namaqondo obushushu angaphezu kwama-300 ℃. Irabha ye-Silicone inokuphefumla kakuhle kwaye i-oksijini yokungena kweyona ndawo iphezulu phakathi kweepolima zokwenziwa. Ukongeza, irabha ye-silicone nayo ineempawu ezibalaseleyo zokungazinzi komzimba kwaye ayibangeli i-coagulation, iyenza isetyenziswe ngokubanzi kwicandelo lezonyango.

- VITON(FKM FPM):VITON O-RING

inokumelana nobushushu obugqwesileyo, ukumelana ne-oxidation, ukuxhathisa kwe-oyile, ukuxhathisa ukubola, kunye nokumelana nokuguga emoyeni, kwaye isetyenziswe ngokubanzi kwiindawo ezifana ne-aerospace, i-aviation, izithuthi, i-petroleum, kunye nezixhobo zendlu. Yimathiriyeli engundoqo engenakutshintshwa kumashishini aphambili okhuselo lwesizwe

- HNBR :HNBR O-RING

inokumelana ne-oyile elungileyo (ukuxhathisa kakuhle kwi-oyile yamafutha, i-oyile yokuthambisa, kunye nezinyibilikisi ezinuka kamnandi); Kwaye ngenxa yesakhiwo sayo esigcwele kakhulu, inokumelana nobushushu obuhle, ukumelana nokugqwesa kweekhemikhali (ukuxhathisa okulungileyo kwiFreon, i-asidi, kunye nealkali), ukuxhathisa okugqwesileyo kwe-ozone, kunye noxinzelelo oluphezulu olusisigxina lokumelana nokuguqulwa; Kwangaxeshanye, irabha ye-nitrile ene-hydrogenated nayo ineempawu ezinjengokomelela okuphezulu, ukuxhathisa okuphezulu kokukrazula, kunye nokunganyangeki okugqwesileyo kokunxiba, okuyenza ibe yenye yezona rabha zigqwesileyo ngokusebenza okubanzi.

- CR(neoprene) :I-CR O-RING

kunye neempawu ezintle zomzimba kunye noomatshini, ukuxhathisa i-oyile, ukumelana nobushushu, ukuxhathisa idangatye, ukumelana nokukhanya kwelanga, ukuxhathisa kwe-ozone, ukuxhathisa kwe-asidi kunye ne-alkali, kunye nokumelana ne-chemical reagent. Okungalunganga kukunganyangeki okubandayo kunye nokuzinza kogcino. Inamandla aphezulu okuqina, ubude, ikristale ebuyela umva, kunye nokuncamathela okulungileyo. Ukumelana nokuguga kunye nobushushu. Ioli egqwesileyo kunye nokuchasana kweekhemikhali

I-FVMQ: I-FVMQ O-RING eneempawu ezilungileyo zomzimba kunye noomatshini kunye nokuzinza kweekhemikhali, ezikwazi ukusetyenziswa ixesha elide kwi-200 ℃ kunye nokusetyenziswa kwexesha elifutshane kwi-250 ℃; Indawo ye-brittleness isuka kwi -20 ℃ ukuya -40 ℃; Ukuchasana okugqwesileyo okuphakathi, uzinzo olugqwesileyo ngokuchasene nezinyibilikisi ze-organic, iiasidi ze-inorganic, kunye ne-oxidants, ngakumbi ukuxhathisa okugqwesileyo kwe-asidi; Inokumelana nemozulu ebalaseleyo kunye nokumelana ne-ozone. Emva kokuvezwa kwi-atmosfera iminyaka eliqela, iipropathi zayo zomzimba kunye nezoomatshini zitshintsha kancinci kakhulu, kwaye impembelelo yayo kwi-microorganisms nayo izinzile.

- I-FEPM(Aflas):FEPM O-RING

inozinzo oluhle, ukumelana neekhemikhali, ngokukodwa ukumelana noxinzelelo oluphezulu lwe-acids, i-alkalis, kunye ne-oxidizing agents ezomeleleyo kwiintlobo ezahlukeneyo zamafutha ezithuthi, izithambisi, i-oyile ye-brake, i-mineral oil, kunye ne-oyile ye-silicone, kunye nokumelana okugqwesileyo kumphunga wamanzi aphezulu, amanzi, kunye nokufakelwa kombane. Inomoya ophantsi wokuphefumla kwaye inokusetyenziswa kumaqondo obushushu aphakathi kwe -400 kunye nama-200 ngokukaCelsius

- FFKM :FFKM O-RING

Ine-elasticity kunye ne-thermal kunye nokuzinza kweekhemikhali ze-polytetrafluoroethylene. Ubushushu bexesha elide lokusebenza -39 ~ 288 degrees Celsius, ixesha elifutshane ukuya kuthi ga kwi-315 degrees Celsius, kusekho iqondo elithile leplastiki engaphantsi kobushushu be-embrittlement, ilukhuni kodwa ingabi brittle, kwaye inokugoba. Izinzile kuzo zonke iikhemikhali ngaphandle kokudumba kwi-solvents ene-fluorinated. yeyona Rabha ibiza kakhulu ngoku ehlabathini.Uphawu: Kalrez

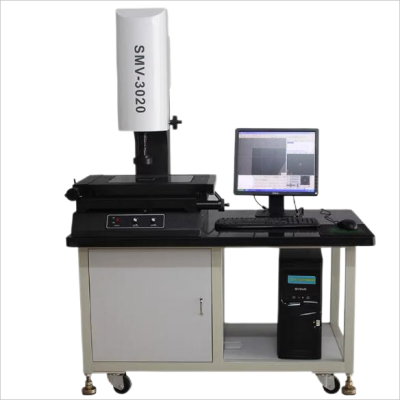

Okwesihlanu- irabha ye-O-ring iinkcukacha Iindlela zokulinganisa kunye nezixhobo.

Izixhobo zokulinganisa eziqhelekileyoYiba:

1-Iprojektha echanekileyo ephezulu

Iimpawu zesixhobo: Imilinganiselo engaqhagamshelwanga, yenza umlinganiselo ungabonakali kwaye ulungele ukulinganisa iindawo ezinodonga olucekethekileyo kunye nezithambileyo; Inomsebenzi oqinileyo wokukhulisa umfanekiso kunye nekhono elinamandla lokulinganisa ubungakanani obuncinci; Isantya somlinganiselo okhawulezayo siphucula kakhulu ukusebenza komlinganiselo; Ubuninzi beendawo zesampulu buqinisekisa ukuthembeka okuphezulu komlinganiselo; ukucofa okufanelekileyo.

I-2-icaliper yedijithali ye-elektroniki

Isixhobo Isisombululo esiqhele ukusetyenziswa ngu-0.01mm, kunye nempazamo evumelekileyo ye-± 0.03mm/150mm. Kukho kwakhona i-high-precision calipers yedijithali enesisombululo se-0.005mm, kunye nephutha elivumelekileyo le-± 0.015mm / 150mm. Kukwakho i-multi-purpose digital display micrometer caliper enesisombululo se-0.001mm (eyi-patent yesizwe ye-Anyi yokulinganisa izixhobo kwaye kuphela banokuyivelisa), ngempazamo evumelekileyo ye-± 0.005mm/50mm. Ngenxa yokufunda okucacileyo kunye nokucacileyo, ukusebenza komlinganiselo kuphezulu.

3-π umlawuli(I-PITAPE)

Iimpawu zesixhobo :

1. Irula engu-π yenziwe ngentsimbi elastiki. Iziphelo zayo ezimbini zikrolwe ngokulandelelana kunye nabalawuli abaphambili kunye nabancedisayo. Ubuncinci bexabiso lokugqiba umlawuli oyintloko ngu-0.5mm okanye 1mm; Awona maxabiso aphantsi okugqiba kwirula encedisayo ngu-0.02mm, 0.05mm, 0.01mm, 0.1mm, njl.

2. Xa usetyenziswa, songela irula π ujikeleze umsebenzi kwaye usebenzise indlela yokufunda yevernier ukufunda ngokuthe ngqo i-avareji yedayamitha yesiqhekeza esilinganisiweyo.

- Izinto eziluncedo nezingeloncedo

(1). Ukuchaneka okuphezulu: Njengoko i-diameter ilinganiswa ngomjikelezo werula π, impazamo yokumakisha ngexesha lokwenziwa kwerula ingancitshiswa ngamaxesha ka-π kwaye iboniswe kwiziphumo zomlinganiselo. Ngoko kwi-φ Kwimilinganiso yobubanzi obukhulu ngaphezu kwe-500mm, ukuchaneka kwayo kuphezulu kunoko kwe-vernier caliper. hlala φ Le nzuzo ibalasele ngakumbi kwimilinganiselo engaphezu kwe-1000mm.

(2). Xa ulinganisa iinxalenye zentsimbi ngerula π, ayichatshazelwa bubushushu bomsebenzi. Oku kungenxa yokuba irula π ibhityile kakhulu, kwaye iya kuba yinto enye kunye neqhekeza elivavanyiweyo ngexesha elifutshane kakhulu ngexesha lomlinganiso. Ukongezelela, ii-coefficients zabo zokwandisa i-thermal zisondele kakhulu, ngokusisiseko zinqoba impembelelo yokushisa.

(3. Kwimilinganiselo yobukhulu obukhulu kunye nobukhulu obukhulu, ukusetyenziswa kwezinto ezincedisayo (iibhulorho ezinobuchwephesha obunelungelo lobunikazi) zivumela ukuba kube lula ukusebenza ngumntu omnye ngexesha.

(4). Ukulinganisa iindawo ezinodonga olubhityileyo akukho lula ukubangela ukuguqulwa komsebenzi. (5). Kukulungele ukuthwala nokugcina (6). Ixabiso liphantsi.

(7). Ububi: Ayikwazi ukutshixa ufundo; Ukuphambuka kwejometri njenge-ovality ayinakulinganiswa.

Okwesithandathu Ukusetyenziswa kwe-O-ring kunye nokufakwa kwe-o-ring.

1. Ukusetyenziswa kwe-O-ring

I-O-ring isetyenziswa ngokubanzi kwiindawo ezidibeneyo ze-hydraulic kunye ne-pneumatic components, i-cylinder surfaces, kunye ne-flange surfaces. Kwiindandatho ze-O ezisetyenziswe ngexesha lokunyakaza, xa uxinzelelo lokusebenza lungaphezu kwe-9.8Mpa kwaye luphantsi koxinzelelo lwe-unidirectional, indandatho yokugcina kufuneka ifakwe kwelinye icala le-O-ring kwicala loxinzelelo; Ukuba uphantsi koxinzelelo lwe-bidirectional, faka i-ring retaining kumacala omabini e-O-ring. Ukunciphisa ukukhuhlana, iiringi zokugcina ezimile okwe-wedge nazo zingasetyenziswa. Xa ulwelo loxinzelelo lusetyenziswa ukusuka ngakwesobunxele, ikhonkco eligcinayo lasekunene lityhalelwa phezulu, kwaye umsesane obambeleyo wasekhohlo awudibani nomphezulu otywiniweyo, ngaloo ndlela unciphisa amandla okubetha. Ngokubanzi, ukusetyenziswa kwamakhonkco okugcina kwandisa amandla okukhuhlana kwesixhobo sokutywina, kwaye amakhonkco okugcina amise okweweji abaluleke kakhulu ekwehliseni la mandla okukhuhlana. Kwi-fixed O-rings, indandatho yokugcina iyafuneka kwakhona xa uxinzelelo lokusebenza lukhulu kune-32Mpa.

2. Ukufakwa kwe-oring

Umgangatho wofakelo lwe-O-rings unempembelelo enkulu ekusebenzeni kwabo kokutywinwa kunye nobomi benkonzo. Iingxaki zokuvuza zivame ukubangelwa kukufakwa kakubi.Ngexesha lokufakwa kwenkqubo, akuvumelekanga ukuba i-O-ring ikrwelwe, ingahambi kakuhle, okanye ijijwe. Ngaphambi kokuhlanganisana, i-groove yokutywina kunye nokutywinwa kwendawo yokukhwelana kufuneka icocwe ngokungqongqo; Kwangaxeshanye, sebenzisa igrisi yokuthambisa kumphezulu ekufuneka igqithe ngexesha lokudityaniswa kwe-O-ring.Ukuthintela i-O-ring ukuba inganqunyulwa okanye ikrwelwe ngamacandelwana abukhali njengeekona ezibukhali kunye neentambo ngexesha lofakelo, i-angle ye-15 º ukuya kwi-30 º yokukhokela kufuneka ishiywe ekupheleni kwe-shaft kunye nokuphela komngxuma wofakelo. Xa i-O-ring idinga ukudlula kwintambo yangaphandle, i-sleeve ekhethekileyo yesikhokelo yentsimbi enqabileyo kufuneka isetyenziswe ukugubungela intambo yangaphandle; Ukuba i-O-ring idinga ukudlula kwi-orifice, i-orifice kufuneka iguqulwe ibe yi-diagonal shape ehambelanayo ukukhusela imikrwelo kwi-O-ring. I-engile yokuthambeka kwegroove ngokuqhelekileyo yi-a=120 º~140 º

Unokufunda ulwazi oluninzi olunxulumeneyo apha. Kamva, siza kwazisa ulwazi malungaamatywina oyile, isitywina se-hydraulic,okanye enyeiindawo zerabha ezilungiselelweyo,njengeItywina yeoli yekati, Itywina yeoli ye-NBRItywina leoli yeFKM,TC ioli yetywina,I-oyile ye-TB isitywini se-oyile ye-TA, itywina le-oyile ye-SCpiston itywina, intonga itywina ,itywina lasentwasahlobo ,itywina elidityanisiweyo, ikomityi yetywina, itywina lothuli,Wiper itywina,nxiba iring ,back up ring ,iintambo zerabha, iintambo ze-o-ring,ngoko sifuna ixesha elingakumbi sazise olu lwazi kumntu wonke. Enkosi ngexesha lakho !

Sinyanzelisa ukubonelela ngemveliso esemgangathweni enengqiqo yeshishini elilungileyo, umvuzo onyanisekileyo kunye noncedo olulungileyo nolukhawulezayo. akuyi kukuzisela kuphela i-premium yekhwalithi yemveliso okanye inkonzo kunye nenzuzo enkulu, kodwa mhlawumbi eyona nto ibalulekileyo idla ngokuhlala kwimarike engapheliyo ye-Wholesale Price I-China As568 Standard Rubber O Ring Silicone O-Ring Color Rubber O Umenzi weRingi, Ukuba kunokwenzeka, qiniseka ukuba uthumela iimfuno zakho ngoluhlu oluneenkcukacha ezibandakanya isitayile / into kunye nobungakanani obufunayo. Siza kuthumela amaxabiso ethu amakhulu kuwe.

Ixabiso leWholeyile yaseTshayinaChina FKM O Ring kunye Rubber O Ring, Ubuchwephesha bethu bobugcisa, inkonzo elungele umthengi, kunye nentengiso ekhethekileyo isenza ukuba / igama lenkampani libe ukhetho lokuqala lwabathengi kunye nabathengisi. Kudala sikhangela umbuzo wakho. Masiseke intsebenziswano ngoku!